Flange Insulating Gasket Kits

Type E Insulation Gaskets

Type E is a full-faced gasket with the same outside diameter as the flange and precision cut bolt holes. This design facilitates proper alignment of the gasket during installation and foreign material prevented from shorting the flange isolation.

Type E gasket are available in plain face or Nitrile faced phenolic, as well as variety of high temperture materials.

Standard thickness of 1/8".

Type F Insulation Gaskets

Type F gaskets are made to fit the raised face portion of the flange only.

As there are no bolt holes in the "F" gasket. the inside diameter of the bolt hole circle is slightly smaller than the outside diameter of the gasket. Assuring an exact, automatic positioning of the gasket. Type F Gaskets are available in the same materials as the Type E Gaskets.

Standard thickness of 1/8".

Dielectrics flange kits

Neoprene-Faced Phenolic

Neoprene-faced phenolic material is a high-performance composite designed for sealing and insulating, primarily in the oil and gas distribution industries. This product features a phenolic core with a chemically bonded neoprene face. Traditional materials often pose challenges—being either too soft to withstand the compressive forces of mating surfaces or too hard to form an effective seal. The combination of neoprene and phenolic offers a perfect balance, with the core providing high compressive strength to prevent the compression issues common with softer materials. This gasket also serves as electrical insulation between the surfaces, reducing electrolytic effects that lead to corrosion. Advantages and Benefits •Highly reliable for low-pressure applications •Exceptional insulation properties for cathodic protection •Extremely low leak rate •Sized to the bore to protect flange faces from media-induced corrosion and flow-induced erosion •Prevents turbulent flow at flanged connections •Mitigates galvanic corrosion between dissimilar metal flanges •Available in various flange specifications (ASME, API, DIN, HG, GB, and more) •Easy installation, assembly, and removal

T-seal Insulation Gasket

T-seal Insulation Gasket The T-seal insulation gasket is specifically designed for flange sealing and insulating in critical service environments. It is compatible with raised face, flat face, and ring-type joint flanges, and supports all pressure classes from ANSI 150 to 2500# and API 2000 to 10K psi. Known globally for its superior sealing capabilities and excellent dielectric properties, T-seal provides reliable solutions across various industries. The gasket material features a glass-reinforced epoxy laminate bonded to a stainless steel core, combining the strength of a traditional metallic gasket with complete electrical insulation between flange faces. Machined seal grooves in the insulating material and stainless steel core provide a robust base for the seal to seat, effectively preventing leaks inherent to glass laminate materials. Spring-energized PTFE internal face seals are fitted into the dovetail-shaped grooves to ensure reliable, long-lasting sealing performance. Advantages and Benefits •Extremely reliable sealing and insulating solution for all critical services •Seals and insulates at pressure classes from ANSI 150 to 2500# and API 2000 to 10K psi •Withstands severe service conditions including bending moments, vibration, temperature, and pressure cycling •Designed for corrosive environments, including high concentrations of CO₂, H₂S, and produced water •Outstanding insulation properties for cathodic protection •Pressure-activated seals ensure high-confidence sealing and prevent costly leaks •Sized to the bore to protect flange faces from media-induced corrosion and erosion •Prevents turbulent flow at flanged connections •Mitigates galvanic corrosion in dissimilar metal flanges •Available in various flange specifications (ANSI, API, MSSP, BS, DIN, AS, etc.) •Can mate mismatched RTJ with raised-face flanges •Easy installation, assembly, and removal •Provides 100% protection from media-induced corrosion in RTJ flanges with ring gasket applications Applications •High-pressure applications (up to 2500# and API 10K psi) •Critical services, including H₂S/CO₂ and high pH environments •Situations requiring an integral seal element •Mismatched flanges, where RTJ mates with RF

Oseal Insulation Gasket

Purpose: Designed for electrical flange insulation in low-pressure services, suitable for raised face or flat face flange connections (not for ring type joints) up to ANSI 600#. Type: Available in Type F (ring type) and Type E (full face). Often used where electrical flange insulation and corrosion control are required. Design Features: •Retainer with two staggered dovetail-shaped seal grooves on both sides, featuring elastomeric sealing elements (rubber O-ring or spring-energized PTFE seal). •Breaks the path between laminated retainer layers, ensuring reliable sealing under low bolt load. Advantages and Benefits: •Highly reliable for low-pressure services. •Seals and insulates in environments up to ANSI 600# pressure class. •Resistant to corrosive environments, including CO2, H2S, and produced water. •Offers excellent insulation for cathodic protection. •Pressure-activated seals eliminate costly leaks. •Bore-sized gasket protects flange faces from corrosion and erosion. •Prevents turbulent flow at flanged connections. •Reduces galvanic corrosion in dissimilar metal flanges. •Available in multiple flange specifications (ANSI, API, MSSP, BS, DIN, AS, etc.). •Easy to install, remove, and reuse. Applications: •Low-pressure systems up to 600# (raised face and flat face flanges). •Ideal for water, gas, oil, and hydrocarbon services. •Suitable for H2S/CO2 and high pH services. •Designed for systems where integral seal elements and low bolt loads are preferred. Retainer Material: •Thickness: 3.2 mm •GRE material available in G10 (green) or G11 (brown).

Type "D" Ring Type Joint Gasket

Purpose: Type "D" Ring Insulation Gaskets offer extreme reliability for sealing and insulation in critical services, including applications with pressures up to 15,000 psi. These gaskets provide a high-performance solution for all pressure classes. Description: Type D gaskets are specifically designed to fit into the ring groove of ring-type-joint (RTJ) flanges. Manufactured from medium weave, fabric-reinforced phenolic material, they are available in both oval and octagonal shapes, meeting ANSI specifications. Applications: •Suitable for high-pressure services, including up to 15,000 psi. •Used in critical services where both sealing and electrical insulation are required. Available Options: •BX gaskets with pressure ratings up to 15,000 psi.

One-Piece Sleeve and Washer Set

Purpose: Designed for flange isolation, these kits include components that help prevent galvanic corrosion and ensure electrical isolation in bolted flange connections. Kit Components (per bolt): •One washer. •One G-10 washer. •One G-10 isolating sleeve. Application Considerations: •Easier to install due to the one-piece sleeve design. •One-piece sleeves offer a clear visual indicator for inspectors to verify correct sleeve usage. Single Washer Set Purpose: This flange isolation kit is designed to provide electrical isolation in flange connections, allowing for cathodic protection in buried applications. Kit Components (per bolt): •One 1/8” thick steel washer. •One isolating washer. •One isolating sleeve. Application Considerations: •In buried applications, the single washer configuration allows cathodic protection (CP) current to reach the nuts and bolts. •Nuts on the opposite side of the cathodically protected flange can be included as part of the CP system, if desired. Double Washer Set Purpose: This flange isolation kit provides enhanced electrical isolation, helping prevent potential “shorting out” of nuts and bolts while offering double protection against corrosion. Kit Components (per bolt): •Two 1/8” thick steel washers. •Two isolating washers. •One full-length isolating sleeve. Application Considerations: •The double washer configuration provides extra protection against "shorting out" the nuts and bolts. •This setup ensures electrical isolation of the nuts and bolts from both flanges, enhancing durability and corrosion resistance.

Insulating Flange

Manufactured in compliance with the size and standards of the compounds used, insulating flanges are among the most reliable and widely utilized solutions for electrical isolation in pipelines. An insulation insert is placed between two end fittings (flanges), ensuring high integrity and completely preventing stray currents from passing from one section of the pipeline to another. Typically, these insulating inserts are made from high-dielectric materials such as Polyamide (PA6) or Teflon (PTFE). The material choice depends on the temperature and chemical resistance requirements of the product being transferred. This product is commonly used at oil berths and transshipment terminals, particularly at the junction between pipes and flexible connections (hoses) used for transferring products. When properly selected and installed, insulating flanges can function effectively for up to 10 years. The materials used in these products do not react with the pipeline contents or the environment, are resistant to aging, UV radiation, and maintain high dielectric resistance, with a minimum of 1000 ohms. Manufacturing Standards: Our company manufactures insulating flanges for all diameters of flanged joints according to the standards of: •German Institute for Standardization (DIN) •American Association Standards (ASA/ANSI) •Japan Industrial Standards (JIS) We also offer custom, non-standard versions upon request. Product Advantages: •No reduction in the diameter of the through passage •No oscillation or loss of working pressure •High resistance levels (ohms) •Guaranteed prevention of stray currents, even with kerosene flow rates up to 4.7 m/s Manufacturing and Quality Assurance: All of our products are manufactured using CNC-controlled equipment, ensuring maximum precision and ease of use. The materials we use for production are sourced exclusively from world-class manufacturers within the European Union. Upon delivery, you will receive manufacturer quality certificates for the materials and certified hydrostatic test reports at the maximum operating pressure.

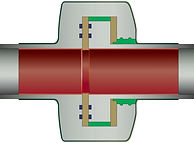

Monolithic Isolation Joints (MIJ)

Purpose: Monolithic Isolation Joints serve as a reliable, long-lasting barrier against the flow of electric current in piping systems. These joints effectively eliminate short circuits, reduce maintenance costs, and improve system reliability. Description: •Eliminates Short Circuits: MIJ fittings remove the need for bolts, sleeves, and washers, which are often the source of short circuits in isolation assemblies. •Eliminates Field Assembly: These fittings come completely factory assembled and tested, reducing the risk of fluid leaks due to improper field assembly. •Cost-Effective: MIJs are less expensive compared to the component parts of traditional insulated flange assemblies. Installation costs are also lower. •Coated Internally and Externally: The fitting is coated with a two-part epoxy, applied to a thickness of 0.010–0.012 inches, within 2 inches of each weld end. •Hydrostatically Tested: Each MIJ undergoes hydrostatic testing at 1.5 times the rated operating pressure, ensuring the fitting’s strength under pressure. •Electrically Tested: All MIJ fittings are subjected to electrical resistance and voltage tests before shipment. •Weld Inspection: All welds are inspected using ultrasonic (UT), magnetic particle (MT), and dye penetrant (LT) methods. X-ray tests are available upon request. Specification: •Monolithic isolation fittings must be boltless, factory-assembled, and compliant with ASTM, API, DIN, and BS codes. •Welds should be butt-weld construction, with dielectric isolation materials made from thermosetting fiberglass epoxy. •Seals must consist of two static, self-energized O-ring seals, housed in accurately machined grooves. •The interior and exterior of the fitting must be coated with a two-part epoxy (12–15 mils thick), extending 2 inches from each end. •Testing: Electrical (5 kV, 25 MΩ), Hydraulic (1.5 x O.P.), and Weld (Ultrasonic/Magnetic Particle/Dye Penetrant).

Insulating Flange Type IHF

Components: •Bolts with nuts •Insulating bolts •Steel washer •ISO washer •Seal •Insulating flange Description: The insulating flange connection type IHF is designed for the safe electrical separation of steel pipes in connection with a CCP system (cathodic corrosion protection system) and for "black and white connections" to protect against bimetallic corrosion. This insulating flange connection is suitable for gaseous media (including gases according to G 260) and liquid media. It is built to withstand typical operating loads without issue, provided it is correctly installed, and it fully meets its functional requirements. The insulating flange connection does not need to be disassembled during the pressure test (test pressure max. 1.5xDP) of the pipeline, and it can remain in place. Unlike the IHF-Q system from ISOflanges, the IHF system is not state-of-the-art, requires mechanical maintenance, and is not permanently sealed according to TRBS 2141-3 and TRBS 2152-2. Regular leak testing (such as according to G495) is required. ________________________________________ IHF-Q (High Performance) Components: •High mechanical strength due to compact construction •Thrust rings •Insulating rings •Metal-to-metal contact seals •Optional compensation ring Description: The insulating flange connection type IHF-Q is used for the safe electrical separation of steel pipes in connection with a CCP system (cathodic corrosion protection system) and for "black and white connections" to protect against bimetallic corrosion. This insulating flange connection is suitable for gaseous media (including gases according to G 260) and liquid media. It is designed to withstand typical operating loads without issue (provided it is correctly installed) and fully complies with its functional capabilities. The insulating flange connection does not need to be disassembled during the pressure test (test pressure max. 1.5xDP) of the pipeline, and it can remain in place. Unlike other insulating flange systems currently available, the IHF-Q system is state-of-the-art, mechanically maintenance-free, permanently sealed in accordance with TRBS 2141-3 and TRBS 2152-2, resistant to additional pipe forces, and allows for the maximum permissible bolt utilization (>70% Rp0.2).

Flange Insulation Band

Our Flange Isolation Bands are engineered to safeguard studs and gaskets on raised face and ring-type joint flanges from the effects of atmospheric corrosion, commonly found in environments such as chemical plants, refineries, gas plants, offshore platforms, onshore oil fields, ships, paper mills, and underground pipelines as well as to prevent stray currents which cause undo corrosion and eventual breakdown of the metal. This system effectively eliminates the risk of foreign matter getting lodged between flange faces or corrosion bridging, which can create an electrical short. Flange Isolation Bands are available in stainless steel or plastic, and are designed to prevent corrosion between flanges in piping systems. These bands are manufactured in compliance with ANSI B16.5 specifications for sizes up to 24″. For flanges above 24″, please provide the specifications, including circumference, for custom fabrication. Our team also offers technical assistance upon request to ensure proper selection and installation. Protect your systems from costly corrosion with our durable and reliable flange isolation solutions. The band includes: •A 316 stainless steel band lined with expanded PTFE, offering chemical resistance and dielectric strength up to 400°F (204°C) (other materials available upon request) •All-stainless steel worm gear drive to tighten the band around the flange •All-stainless steel grease fitting for inserting corrosion inhibitor-type grease •Positive loading relief vent and inspection plug

Contact

SIA "Tehnisko Materiālu Sagāde"

Ramulu street 23 Riga,Latvia LV-1005

+371 22114858

+371 22114878

Mon-Fri 9:00 - 17:00

Sat,Sun -